Material handling is an essential part of many industrial processes. Whether it is in the food processing, packaging, or manufacturing industry, the efficient handling of materials is critical for the success of any operation. The use of small screw conveyor systems has made material handling easier, faster, and more effective. In this article, we will explore how small screw conveyor systems work, the benefits of using them, and how they can improve your business processes.

What is a Small Screw Conveyor System?

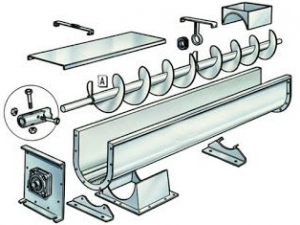

A small screw conveyor system is a mechanical device that is used to move materials from one point to another. It consists of a screw, a trough, and a motor. The screw is the main component of the system, and it rotates inside the trough, pushing the material forward. The motor provides the power to turn the screw, and the trough acts as a container to hold the material.

How Does a Small Screw Conveyor System Work?

The operation of a small screw conveyor system is straightforward. The material that needs to be moved is placed in the trough, and the screw is started. As the screw rotates, it creates a force that pushes the material forward. The speed of the screw can be adjusted to control the rate at which the material moves. The trough is designed to prevent the material from spilling over the sides, and it can be customized to fit the needs of the application.

Benefits of Using Small Screw Conveyor Systems

Small screw conveyor systems have a wide range of benefits that can improve your business processes. Here are some of the most significant advantages of using small screw conveyor systems:

1. Increased Efficiency

Small screw conveyor systems can move material quickly and efficiently. They can move material at a rate of up to 550 cubic feet per hour, depending on the size of the screw and the motor. The speed of the system can also be adjusted to match the needs of the application, making it easy to increase or decrease the rate of material flow.

2. Reduced Labor Costs

Small screw conveyor systems can reduce the need for manual labor in material handling. They can operate continuously without the need for human intervention, which can reduce labor costs and increase productivity. Additionally, small screw conveyor systems can be integrated into existing production lines, reducing the need for additional workers.

3. Improved Safety

Small screw conveyor systems are designed with safety in mind. They have guards and covers to prevent accidental contact with moving parts, reducing the risk of injury. They also eliminate the need for workers to manually handle heavy or hazardous materials, which can reduce the risk of injury and illness.

4. Easy Maintenance

Small screw conveyor systems require minimal maintenance. The components are easy to access, making it simple to clean and inspect the system. Additionally, the system is designed to be durable and long-lasting, reducing the need for frequent repairs or replacements.

Applications of Small Screw Conveyor Systems

Small screw conveyor systems can be used in a variety of industries and applications. Here are some of the most common applications of small screw conveyor systems:

1. Food Processing

Small screw conveyor systems are commonly used in the food processing industry to move ingredients and finished products. They can be used to move bulk materials such as flour, sugar, and grains, as well as finished products such as packaged foods and beverages.

2. Packaging

Small screw conveyor systems can be used in the packaging industry to move boxes, bags, and other packages from one station to another. They can also be used to move packaging materials such as boxes, bags, and pallets.

3. Manufacturing

Small screw conveyor systems can be used in manufacturing processes to move raw materials, work-in-progress parts, or finished products. They can also be used to transport materials between machines, speeding up production times and reducing the need for manual labor.

Conclusion

Small screw conveyor systems are an essential part of many industrial processes. They can move materials quickly and efficiently, reduce labor costs, improve safety, and require minimal maintenance. With their wide range of applications and benefits, small screw conveyor systems can improve the efficiency and effectiveness of any business process. If you are looking for a reliable and efficient way to move materials, consider using a small screw conveyor system.